Managing Subsea Asset Integrity in Mature Field

THE QUICK OVERVIEW

WHO: BW Energy Brazil.

WHAT: Systemic assessment, monitoring, testing and inspection of subsea structures.

WHERE: Subsea Integrity Management.

HOW: Integrating Asset Integrity Management application to company processes and decision-making.

WHY: Reduction in operational and capital expenditure, improved early detection of anomalies, enhanced regulatory compliance, and extended asset life.

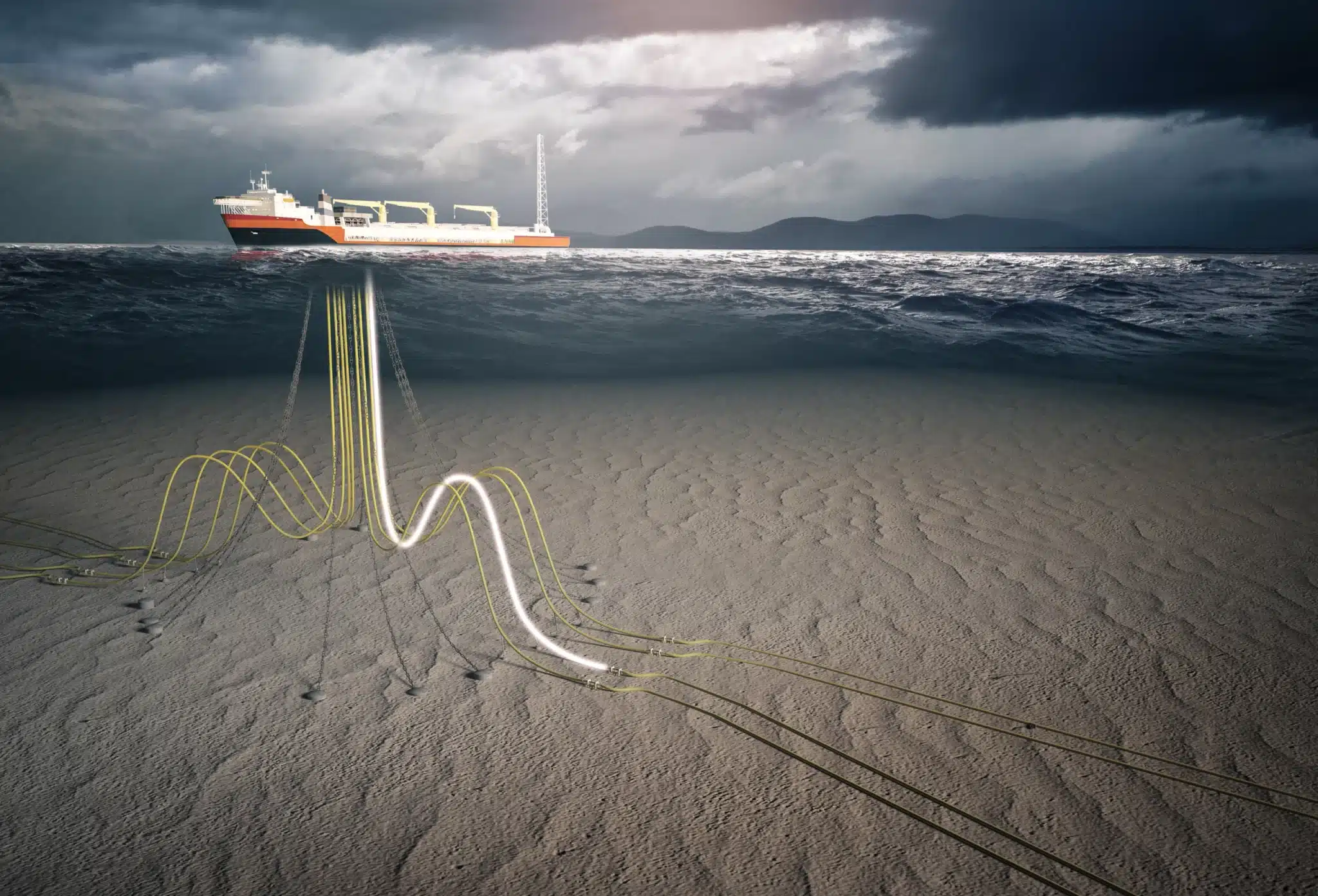

This case study highlights the collaboration between BW Energy Brazil, a growth-focused oil and gas company, and 4Subsea, a provider of advanced digital monitoring solutions and analytics, to address the challenges of managing complex pipeline systems and large volumes of documentation, while supporting the transformation of unstructured data into structured data to improve reliability and accessibility. Additionally, it was paramount that the data needed to be accessible from multiple locations, including offshore installations, onshore departments and third-party contractors.

Client Overview

BW Energy is a growth-focused oil and gas company involved in the acquisition, development and production of proven oil and gas natural fields.

Challenges

Managing complex pipeline systems and large volumes of documentation, while supporting the need for transforming unstructured data into structured data for better reliability and accessibility. Additionally, it was paramount that the data be accessible across multiple locations, including offshore installations, onshore departments, and third-party contractors.

Objectives

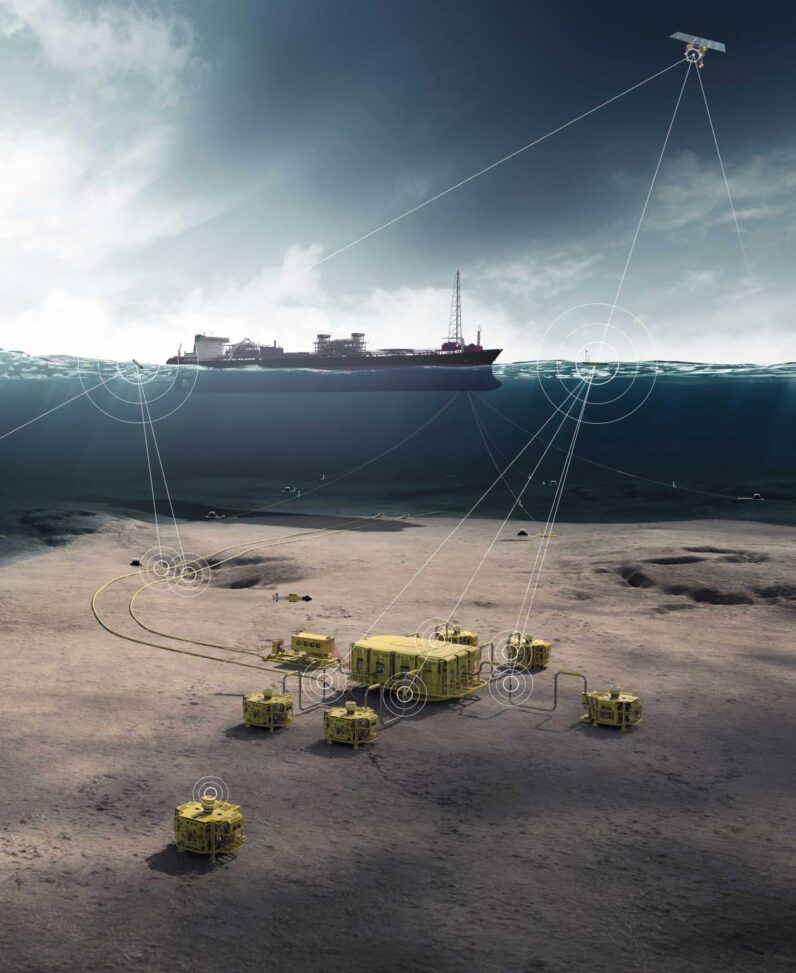

The main objective was to implement a solution that could centralise and structure critical subsea data, including documentation, equipment history, field layout, and anomaly tracking into a single accessible platform. The motivation came from the need to reduce dependency on scattered files and manual processes, as Golfhino is a mature field and a large number of documents were received from its former operator, making it essential to ensure a reliable information flow between offshore and onshore teams, as well as third-party contractors.

By adopting a digital management system with automated processes and intuitive dashboards, BW Energy aimed to increase operational efficiency, data integrity, and collaboration across the entire subsea organisation.

Solution

By implementing the 4Insight Asset Integrity Management application, automated processes were established to reduce the time spent by engineering staff on manually updating tasks previously stored in various offline documents and lists. The platform’s dashboards facilitate better decisions and information sharing based on insights from reliable and timely data that can be accessed simultaneously across different departments and roles in the organisation, as well as third-party contractors to optimise collaboration across onshore and offshore personnel.

The platform plays a critical role in managing the integrity of subsea assets by tracking activities, monitoring risks and facilitating information sharing and insights. By tracking the necessary activities, both short- and long-term, and managing due dates of those activities it becomes easier to plan for future campaigns with all necessary departments (subsea asset integrity, logistics, supply chain etc.) and third-party contractors availing of the exact same data and dashboards.

Results

The first step is to ensure the integrity management plan is updated to visualise risk assessments, asset conditions and determine the frequency and type of activities to be carried out by what personnel.

The Asset Integrity Management application dashboard is easy to use and provides a clear overview of the key activities, anomalies and critical issues. The platform tracks activities with due dates and descriptions that help manage and plan maintenance tasks for the given asset.

4Insight also integrates different monitoring systems like Data Analytics using the PI integration (streaming vessel, weather and sensor data) and FPSO motion monitoring (SMS Gateway), which provide very valuable data (both current and historical) for life extension studies and fatigue assessments enabling proactive interventions where required.

Conclusion

Implementing the 4Insight Asset Integrity Management application, has delivered the following benefits:

- Reduced OPEX/CAPEX spend by avoiding unplanned repairs and replacements.

- Reduced risk by detecting anomalies before they develop into critical operational issues.

- Reduced time spent on finding information and avoiding misunderstandings.

- Increased expected production and investment results by extending lifetime of assets beyond original design life

- Improved access to information to demonstrate compliance with different authorities and regulatory requirements related to integrity management.

The implementation of AIM has already delivered measurable results. Automated data handling and structured documentation have improved efficiency, collaboration, and data reliability across teams. The solution also reduced time spent on manual tasks and facilitated quicker access to information across offshore equipment. The next step is to expand predictive analytics and integrate additional SPS and SURF historical data to further enhance reliability and asset lifetime across the Golfinho field.

Reach out to learn more

Discover how our solutions can create immediate business value for your operations. Connect with us today.