Enhancing Safety in Drilling Operations

The Synergy of SWIM Measurements, Simulations and Engineering.

THE QUICK OVERVIEW

WHO: AkerBP

WHAT: Assess structural impact on the well, verify effectiveness of initiated actions, and provide AkerBP with operating guidelines and fatigue predictions to ensure safe resumption of drilling activities.

WHERE: Aker BP drilling operations

HOW: Emulated the well’s in-situ conditions and created a framework to ensure both safety and efficiency. This included gravel dumping and installation of Wellhead Load Reliefs (WLRs).

WHY: Ensuring safe continuation of drilling operations.

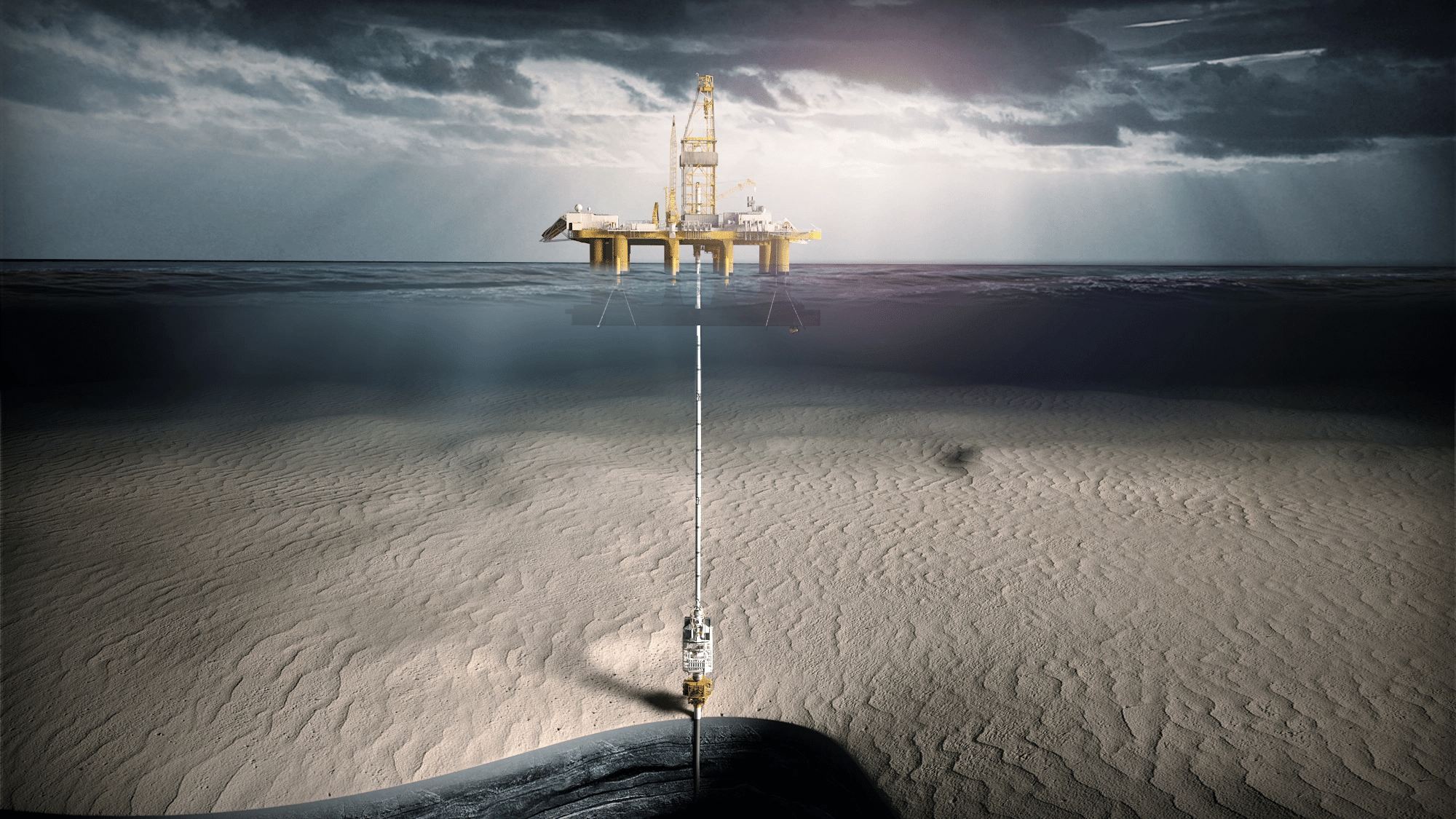

This case study highlights the collaboration between AkerBP, a leading oil and gas company, and 4Subsea, a provider of advanced digital monitoring solutions and analytics, to address and resolve a challenging washout incident during the drilling of a satellite production well. Engineering expertise was key to interpreting the collected data, performing detailed simulations, and implementing effective mitigation measures.

Challenges

Three days into the drilling of a satellite production well, AkerBP encountered an unexpected washout incident that required immediate attention. The Blowout Preventer (BOP) experienced unanticipated movements, and soil erosion in the upper layers reduced support for the conductor. This exposed certain points on the conductor to elevated loads, leading to increased fatigue accumulation and concerns about the well’s structural integrity.

Solution

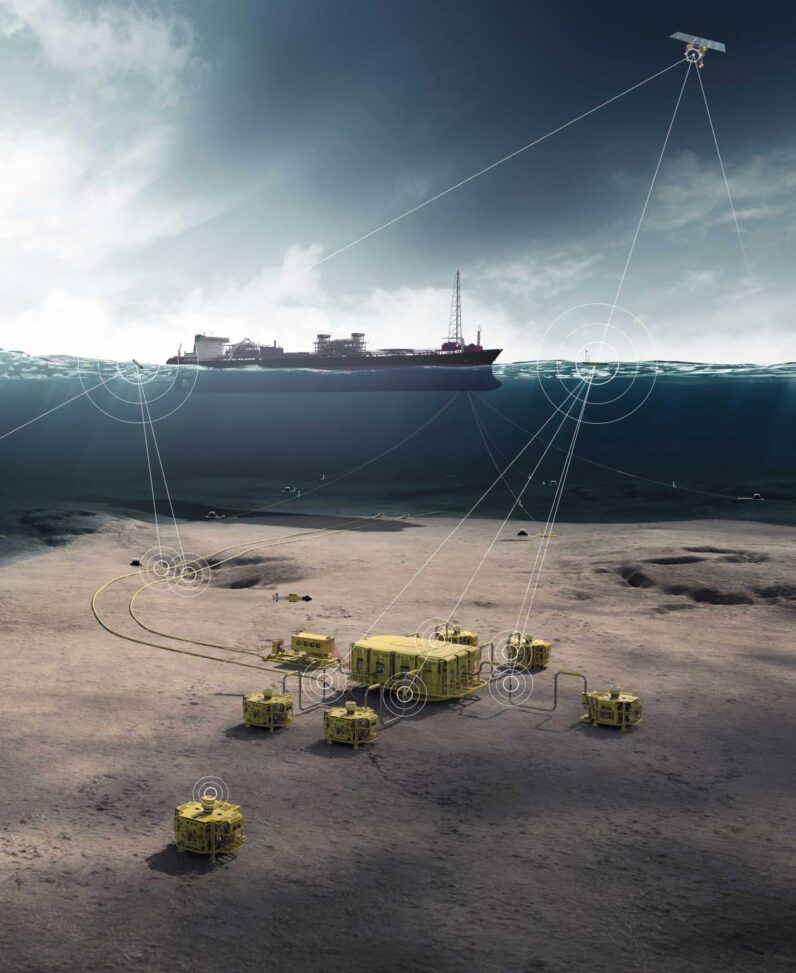

A specialised team from 4Subsea worked closely with AkerBP to assess the situation and develop a tailored response. By integrating SWIM™ measurements with detailed local analyses, 4Subsea engineers were able to replicate the well’s in-situ conditions accurately. This approach delivered valuable insights into the well’s structural behavior and the feasibility of proposed remediation strategies.

Using these simulations, the team defined a ‘window of operations’—a precise framework for conducting drilling activities safely and efficiently under current conditions. Mitigation measures included gravel dumping and the installation of Wellhead Load Reliefs (WLRs) to stabilise the affected area. Ongoing monitoring and simulations allowed for the refinement of operating guidelines and fatigue assessments, ensuring the safe continuation of drilling operations.

Objectives

The main objectives were to evaluate the structural impact on the well caused by the washout, verify the effectiveness of the mitigation measures around the conductor, and provide AkerBP with clear operating guidelines and fatigue assessments to enable the safe resumption of drilling activities.

Results

Through the collaboration between 4Subsea and AkerBP engineers, combined with the innovative application of SWIM™ measurements and simulations, AkerBP successfully addressed the washout incident. The company safely completed drilling operations and transitioned the well to production, demonstrating a robust ability to adapt and maintain operational integrity in challenging conditions.

Conclusion

This case underscores the value of timely, informed decision-making in addressing unexpected challenges during drilling operations. The partnership between AkerBP and 4Subsea highlights how advanced digital monitoring and simulation technologies can support safe, efficient, and successful drilling and well intervention activities.