How to Use Data Analytics to Improve Rig Operations

Odfjell Drilling improved rig operations, developed a new business model and easily shared rig data with clients using 4insight® Data Analytics.

THE QUICK OVERVIEW

WHO: Odfjell Drilling

WHAT: Access sensors and onboard operational rig data with cloud applications for analysis.

WHERE: Odfjell Drilling rigs

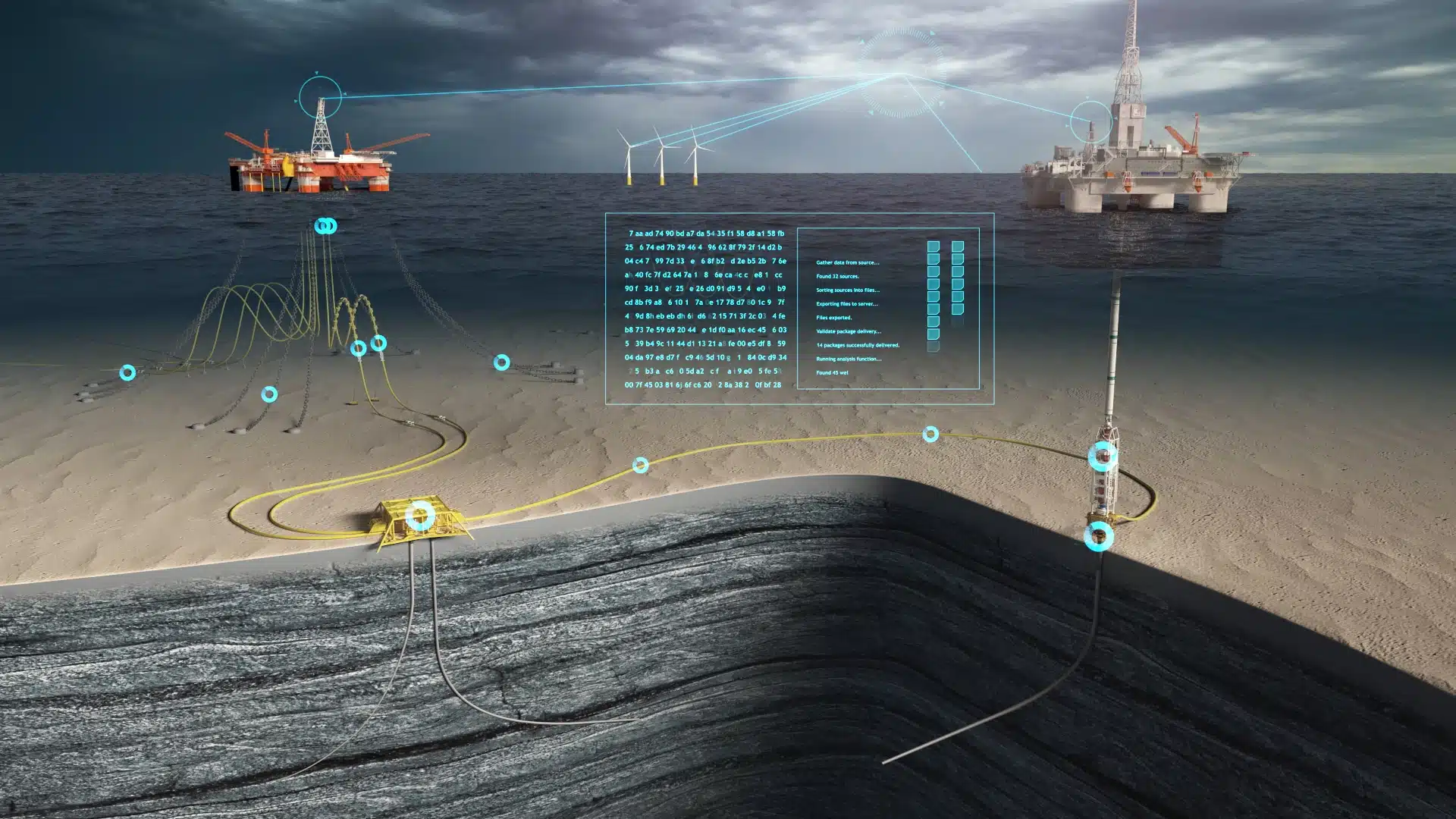

HOW: 4insight® Data Analytics captured time-series data from the rig and pushed it to the cloud, enabling the Odfjell team to make data-driven decisions by performing analysis on different operational parameters.

WHY: Optimised operating procedures, reduced energy and fuel consumption by enabling the crew and engineers to use cloud-based data to make data-driven decisions.

As part of an overall plan to improve rig operations, Odfjell Drilling recognised need to gain digital insight into the performance of their rigs. The challenge was to enable easy access and allow that data to be available to a single cloud application.

Using 4insight® Data Analytics to capture all data as time-series data and uploading the data to the cloud allowed the operations team to gain a comprehensive insight into rig performance. Access to 4insight® was given to Odfjell Drilling and selected clients, enabling them to create their own insights without providing physical access on site.

Background

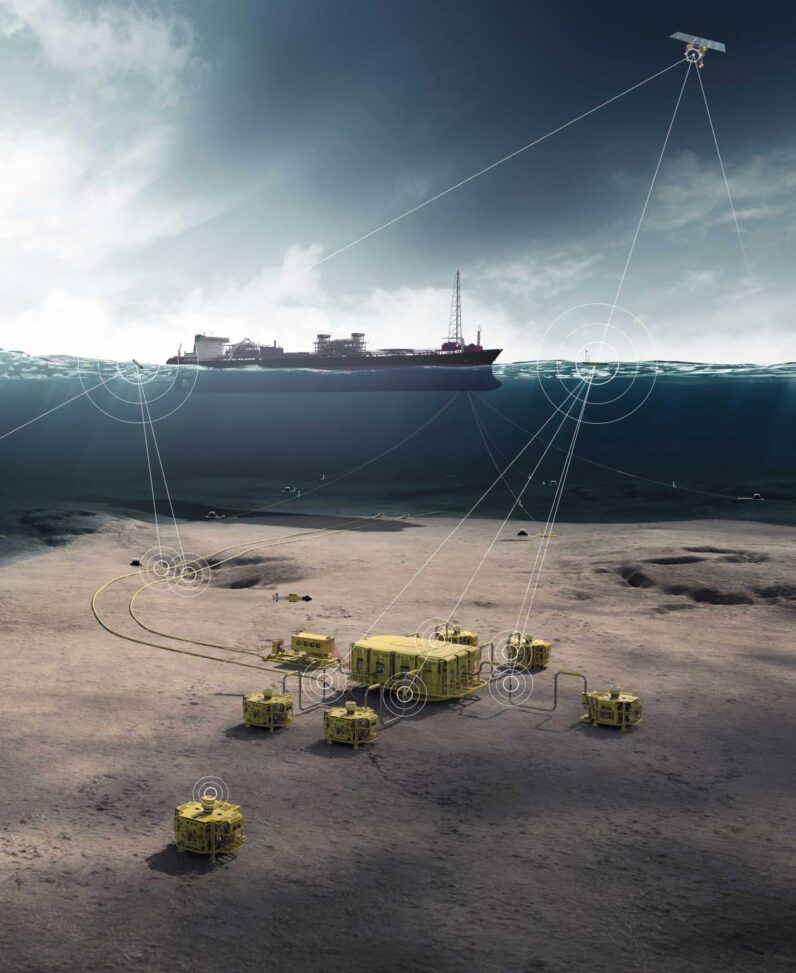

Odfjell Drilling wanted a global overview of their rig operations and fuel consumption to enable them to be more innovative, competitive and offer increased value to their clients, rig operators. The challenge they faced was to gain access to data from several sensors and control panels, siloed in respective vendor control systems on the rig.

A local physical connection had to be established to all control systems whilst ensuring the necessary security and control access to limit cyber security risks. By gaining access to operational and sensor data from their rigs, Odfjell Drilling improved their vessel operation, created new business models, and satisfied their client requirements for secure data access.

Objectives

- Enable the engineers and crew to make data-driven decisions by allowing easy access to sensors and rig operations data by uploading it to the cloud.

- Provide secure access to operational data from rig to clients easily.

Technical Solution

4Subsea’s solution began by deploying a Data Connector to the rig to collect data from various sources. The Data Connector is a component of the 4insight® Data Analytics and interfaces with local sensors and rig control systems, pushing time-series data to DataReservoir.io™, which can handle large amounts of time series data, making that data accessible securely in the cloud. By using 4insight® DataReservoir.io™ APIs, the client could access the collected time-series data to analyse, contextualise and visualise the data for performance insight and informed decision making.

DataReservoir.io™ enables access to the time-series through REST APIs or Python APIs, giving engineers a choice for ingesting the data into their own applications.

Result

With the 4insight® Data Analytics, Odfjell Drilling made important progress on the digital transformation of the rig operations with the data-driven descisions to improve client services:

- Understanding and optimising energy consumption: By monitoring and analysing energy consumption patterns, rig crews could monitor rig performance, share best practices and encourage data-driven operational decisions.

- Business model innovation with fuel data: Monitoring the fuel consumption used in the vessel allowed fuel efficiency to be maximised, saving cost and reducing the environmental impact of operations.

- Data sharing with the client: Odfjell Drilling gave the client access to the required time series data using DataReservoir.io™ APIs. The client could then extract the data directly from the cloud and analyse it for efficient future field development planning.