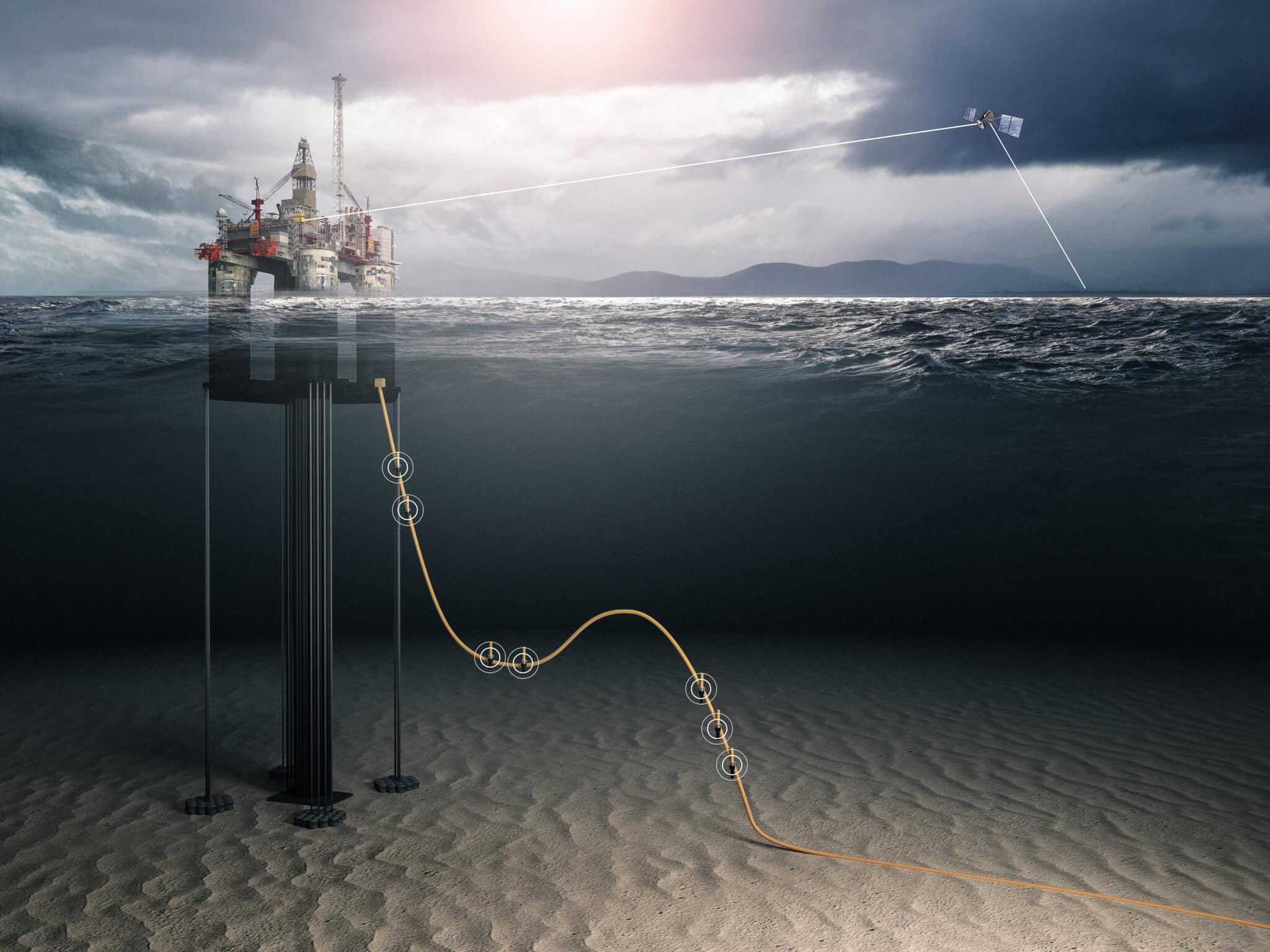

Lifetime Extension Assessment of Subsea Umbilicals Risers and Flowlines

THE QUICK OVERVIEW

WHO: Major Oil and Gas Operator.

WHAT: Lifetime extension assessment of SURF system.

WHERE: Caribbean Sea.

HOW: The Life extension assessment was performed in accordance with the process outlined in the international standards Norsok Y-002 (Transportation Systems) and Norsok U-009 (Subsea Equipment).

WHY: Safe and reliable operation beyond the original design life.

This case study summaries a Life Extension Study completed by 4Subsea for one of the largest global oil and gas companies. Engineering and project management expertise in the specialist field of subsea pipeline integrity management were key to ensuring the work was completed efficiently, on time, and within budget.

Extensive knowledge of design methodologies, failure mechanisms, and inspection and monitoring methods for flexible pipes, rigid pipelines, and methanol umbilicals, enabled 4Subsea to conduct a comprehensive assessment of a complex subsea system. Effective workflow planning and status reporting kept our client informed throughout the project, while close communication among all parties ensured the timely availability of required input data. When unexpected gaps in input data were identified, they were proactively flagged and addressed through ad-hoc discussions and assessments, ensuring a fully informed conclusion on the feasibility of extending the operation beyond the original design life.

Challenges

The Subsea Umbilicals, Risers, and Flowlines associated with one of our client’s assets operating offshore in the Caribbean Sea were nearing the end of their original design life. The client desired to continue operations beyond this period, provided the subsea system equipment could be confirmed as suitable for safe operation beyond its original design life.

Objectives

The primary objective of the assessment was to determine if safe and reliable operation of the SURF equipment beyond its original design life would be feasible.

Approach

The life extension assessment was conducted in accordance with industry’s best practices. The main steps included:

- Data gathering: The required input data for the assessment was collected.

- System overview: The input data was reviewed to understand system’s construction and battery limits.

- Gap analysis: A screening was conducted to identify any critical changes introduced by the latest design requirements. Operating conditions were reviewed against the original design premises to determine if the original design premise remains valid.

- Current condition assessment: The data from the gap analyses, along with inspection and maintenance records, were reviewed to assess the current integrity status.

- Risk assessment: A risk assessment of time dependent threats was carried out to evaluate the feasibility of safe operation until the desired CoP date.

- Reporting: The work completed throughout the assessment, along with the conclusions, was documented.

Due to the complexity of the system, the equipment was split into groups: flexible pipes, rigid pipelines, and methanol umbilicals. This was required to ensure a more focused approach to each type of equipment and to make the assessment process more manageable.

Outcome

- Leveraging deep expertise in failure mechanisms, design methodologies, and monitoring and inspection techniques across pipeline systems, 4Subsea provided a comprehensive, integrated assessment of the client’s complex asset – serving as a one-stop shop for integrity evaluation.

- With extensive experience in life extension studies and project execution, the 4Subsea team delivered the assessment efficiently, on time, and within budget – demonstrating reliability and project discipline.

- The assessment identified critical gaps and vulnerabilities that need to be addressed to ensure safe and reliable operation of the asset beyond its original design life. This insight enabled informed decision-making, proactive maintenance, and long-term cost efficiency for the client.

Reach out to learn more

Discover how our solutions can create immediate business value for your operations. Connect with us today.