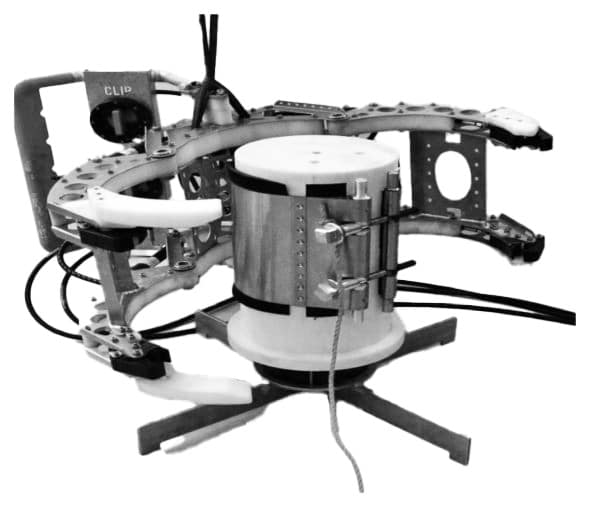

EPIC Riser Repair Clamps

Typical challenges

Do any of these apply to your flexible risers?

- You have an outer sheath breach either above or below sea level that requires a repair

- You lack a good solution to document to maintain your riser integrity

- You need a cost effective solution easily and safely installed either by rope access (above sea level) or by ROV or divers (subsea)

Key benefits

A riser repair clamp may be required based on findings from annulus testing, ROV inspection, or visual inspections. The most common findings are a damaged outer sheath or blocked vent ports. 4Subsea provides repair solutions that can be installed without any loss of production time. We may also undertake overall project responsibility for such projects.

The EPIC™ clamping solutions have been installed on several installations on the Norwegian and British continental shelf, the Dutch sector, Asia and Africa.

-

EPIC™ clamps are designed for long lifetime in harsh offshore

environments and may be installed both as temporary and permanent solutions. -

4Subsea offers long-term repair solutions to reduce risk of pipe failure and ensure maintained production.

-

4Subsea provides repair solutions that can be installed without any loss of production time. We may also undertake overall project responsibility for such projects and perform a fit-for-service assessment of the flexible riser, taking into account the characteristics of the damage, the amount of incurred corrosion and pipe dynamics to document the remaining design life of the flexible pipe.

Key Features

A riser repair clamp may be required based on findings from annulus testing, ROV inspection, or visual inspections. The most common findings are a damaged outer sheath or blocked vent ports. 4Subsea provides repair

- Clamps can be delivered with vent port(s) for re-establishment of annulus ventilation

- Customised to riser outer diameter and size of damage

- Can be produced in super duplex, 6Mo or 316SS with NBR or VitonFKM liner for sealing of the outer sheath breach.

- Light weight design with long lifetime

- EPIC™ ROV clamp is designed for ROV installation, and the operation is performed with a standard work class ROV

- EPIC™ clamps are designed for long lifetime in harsh offshore environments, and are normally installed by divers climbers or from scaffolding

- Clamps may be installed both as temporary and permanent solutions

- Each clamp may be delivered with documentation package, depending on clamp application and client requirements.

Watch a short video demonstrating riser repair subsea:

The EPIC™ Clamp Repair Series

4Subsea offers long-term clamp repair to reduce risk of pipe failure and ensure maintained production. The EPIC™ series provides safe and cost effective outer sheath repair solutions for flexible risers and flowlines. The repair can be performed with no riser downtime and short installation time.

-

Our clamp repair system seamlessly integrates with remotely operated vehicles (ROVs), enabling swift and precise installation even in challenging subsea environments. Equipped with cutting-edge technology, it ensures efficient repair solutions without the need for diver intervention, minimising operational risks and enhancing project timelines.

-

For subsea repairs requiring a more hands-on approach, our clamp repair series offers compatibility with diver installations. Engineered for reliability and ease of use, it facilitates seamless deployment and secure fastening, empowering divers to execute repair tasks with confidence and precision, even at considerable depths.

-

In topside applications where subsea access is not required, our clamp repair system offers a manual installation option. Designed for simplicity and efficiency, it enables quick and straightforward installation by onsite personnel, minimising downtime and maximising operational efficiency for topside repair scenarios.

-

Beyond standard repair solutions, our EPIC™ Clamp Repair Series offers customised options tailored to specific needs. Whether it’s a bespoke repair clamp for addressing leakage in riser end-fittings, re-establishing annulus vents, or incorporating monitoring clamps for equipping sensors or other equipment, our team is equipped to deliver tailored solutions to meet your unique requirements with precision and reliability.

Get in touch

Please feel free to contact us about our solutions or request a demo. We look forward to hearing from you!