- Engineering Services

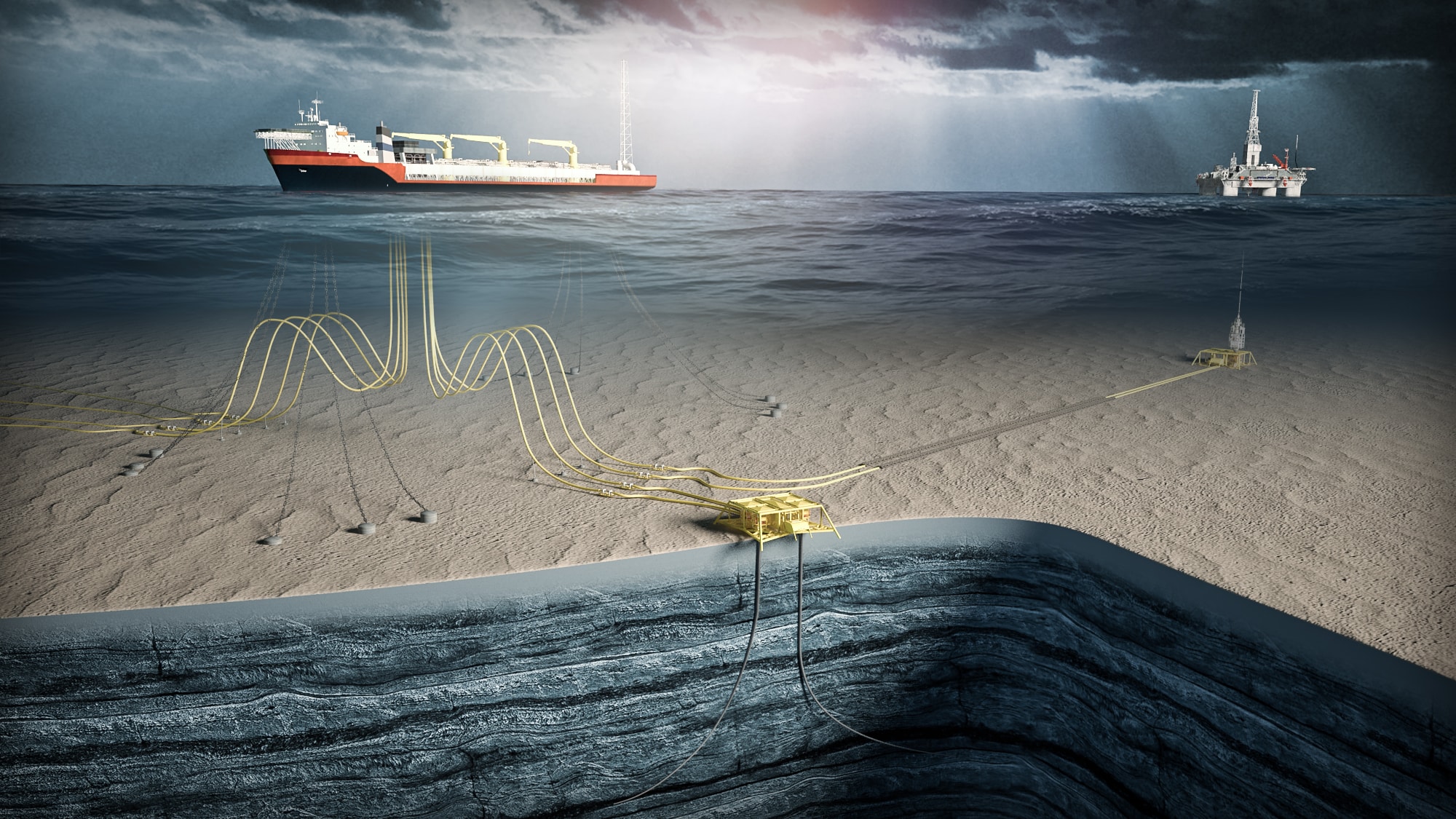

4Subsea ensures the integrity, safety, and longevity of offshore assets with advanced sensors, data analytics, and digital twin technology.

We understand that asset integrity is essential for the safety, extension, and performance of offshore infrastructure. With engineers with decades of experience in subsea engineering and monitoring, we specialise in maintaining the safety and reliability of subsea oil and gas fields through expert engineering, practical experience, and cutting-edge digital technologies.

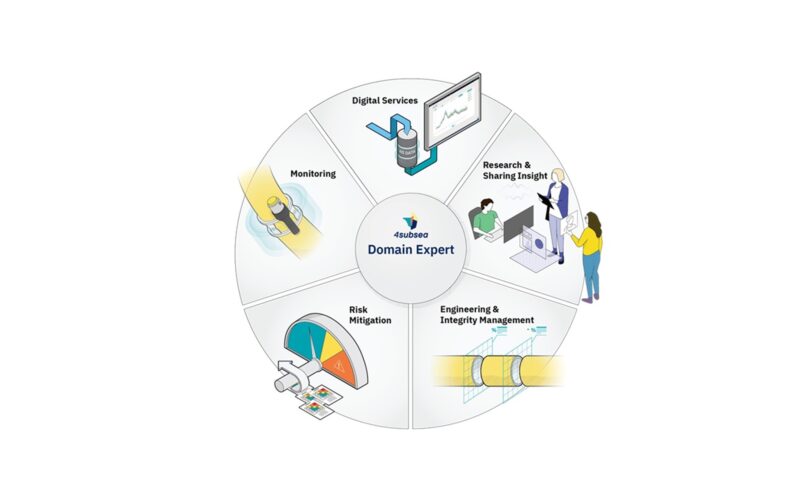

Our solutions empower operators to proactively manage asset integrity, reduce risks, and extend the lifecycle of critical infrastructure. Here’s how we deliver value across five key areas:

Effective integrity management demands deep expertise and practical solutions tailored to operational realities. Our approach integrates regulatory knowledge, risk assessment, and lifecycle planning to address operational challenges.

Digital technology plays a pivotal role in managing the integrity of subsea assets. Our solutions enable operators to replace inefficient processes, improve data accessibility, and monitor asset performance in real time.

The complexity of subsea operations requires continuous learning and collaboration. By engaging in joint initiatives and industry research, such as the FlexShare™ joint operator initiative for flexible pipes, we help operators navigate technical challenges and establish best practices.

Without accurate data, operators face uncertainty in their decision-making processes. Our monitoring systems provide the insights necessary to optimise operations and maintain asset performance.

Managing risks associated with subsea assets requires proactive measures to prevent failures. We offer practical solutions to address potential vulnerabilities before they escalate into costly issues.

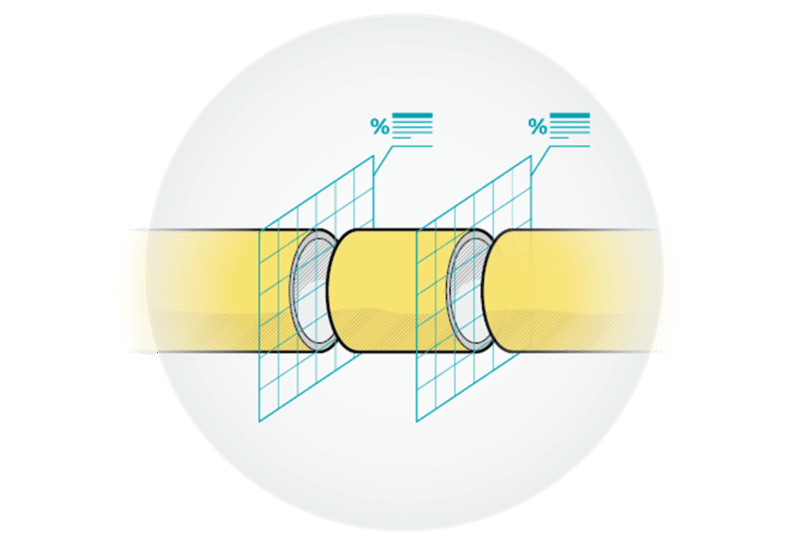

A comprehensive software solution dedicated to the management of subsea asset structural integrity.

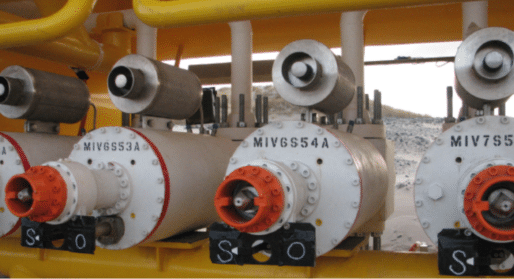

Streamline subsea valve management with ValveTrack

AMOS is a riser vent gas monitoring solution designed to also be easily retrofitted on existing risers. The system monitors the riser annulus diffusion rate, detecting early signs of riser failure, reducing risk and averting potential costly riser replacements.

The EPIC clamp series is a safe and cost-efficient solution for repairing outer sheath damages on flexible risers, umbilicals and power cables. Repair is performed with no production downtime and a short installation time with either manual installation in the splash zone or using ROV or divers subsea. All clamps are provided complete with necessary installation tools including ROV tooling.

PAT is a fully automated tool for integrity testing of the riser annulus of flexible risers either using pressure or vacuum. PAT can also be used as a retrofittable, temporary, or permanent riser vent gas monitoring solution.